2wheelsadam

Member

Anyone have or have used a belly mower on a C? Wondering how good of a job they did of cutting grass. What are the kind and model numbers of decks for the c or supper c ? Thanks

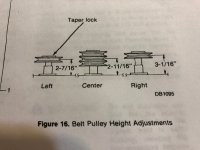

cuznguido":2dp35l28 said:Thank you Rick. Actually there is a jewel in what you said. The verticle alignment of the drive pulley and the idlers may just be something I need to adjust. Already ordered a longer new belt so that some changes can be made. I think I became too fixated on trying to make the original stuff work.

Rick Spivey":mqylchz2 said:... Lastly make sure the left and right sides of the belt are at the same height, as well as being horizontal. ...

Bill Hudson":2f9ugtx1 said:Rick Spivey":2f9ugtx1 said:... Lastly make sure the left and right sides of the belt are at the same height, as well as being horizontal. ...

Hate to disagree with Rick, but on a Woods 59 the outer spindle pulleys are at different heights. Therefore, I wouldn't be surprised if the outside pulleys are in different positions on a wider Woods mower.

My Woods manual is in the Cubhouse now, or I would quote the numbers for you.

Bill

Well, I did start by saying I had no experience with the wider mowers. But I think the overarching consideration is that the belts have a preferred path and and attitude, which an owner should keep intact. Once the belts are allowed to deviate from the intended path, issues like jumping off will happen. Thanks Bill, for the precision and correction, because we want the readers to have correct information above all.Bill Hudson":12a2mj3a said:Rick Spivey":12a2mj3a said:... Lastly make sure the left and right sides of the belt are at the same height, as well as being horizontal. ...

Hate to disagree with Rick, but on a Woods 59 the outer spindle pulleys are at different heights. Therefore, I wouldn't be surprised if the outside pulleys are in different positions on a wider Woods mower.

My Woods manual is in the Cubhouse now, or I would quote the numbers for you.

Bill