Help with Electric Motor Please

Posted: Sun Apr 10, 2011 1:38 pm

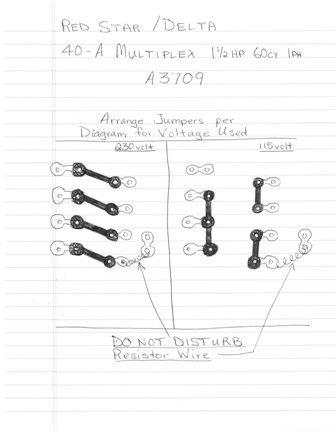

I got a Red-Star/Delta 40-A Multiplex/Radial Arm Saw, that needed a new capacitor...the guy that had it said he put a new plug on the end of the cord to go from 110V to 220V, and he reconfigured the jumpers per the diagram on the motor and when he plugged it in it blew the capacitor. Prior to that, it ran fine on 110V.

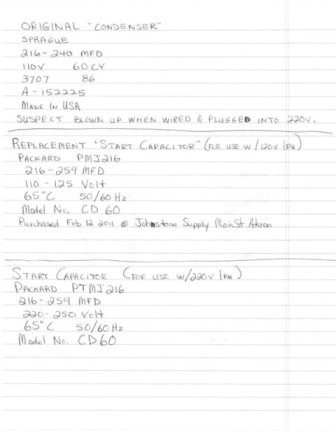

After spending a few minutes with the guys at the electric supply store, I found out that the capacitor he blew up was voltage specific for 110V.

New one was only $7 !

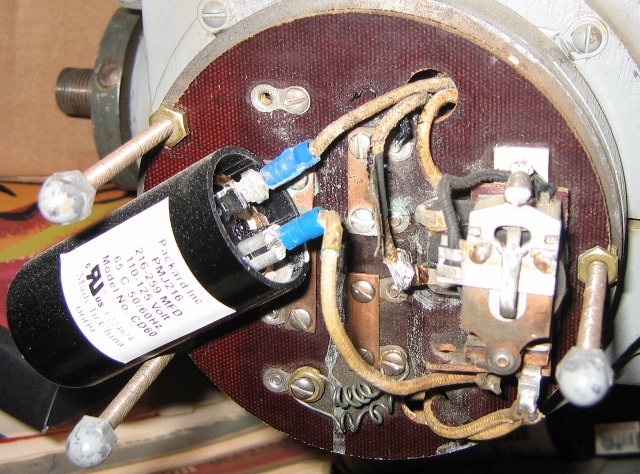

Purchased it, installed it, and reconfigured the jumpers on the board as shown for 110V.

Plugged it in, turned it on, started like a champ and ran for about 15 seconds and blew the new capacitor! ...stinky smoke for sure!

I unplugged it and will need to figure out the next step.

This is a very rugged and over-engineered woodworking product from 1950 that I purchased primarily for the 1-1/2HP motor power and ripping capacity.

Any ideas on what I should do next for troubleshooting would be very much appreciated.

marion

After spending a few minutes with the guys at the electric supply store, I found out that the capacitor he blew up was voltage specific for 110V.

New one was only $7 !

Purchased it, installed it, and reconfigured the jumpers on the board as shown for 110V.

Plugged it in, turned it on, started like a champ and ran for about 15 seconds and blew the new capacitor! ...stinky smoke for sure!

I unplugged it and will need to figure out the next step.

This is a very rugged and over-engineered woodworking product from 1950 that I purchased primarily for the 1-1/2HP motor power and ripping capacity.

Any ideas on what I should do next for troubleshooting would be very much appreciated.

marion