This shows the blade mounted and as originally designed.

I have not yet incorporated any of Jim Becker's ideas about variable blade angle, but will probably do so during the next re-design. Re-design? Whatever for? How does one improve on perfection? Well... it turns out that the initial design already had the ability to vary the vertical blade angle. This was an undocumented design feature that was not appreciated until it was seen.

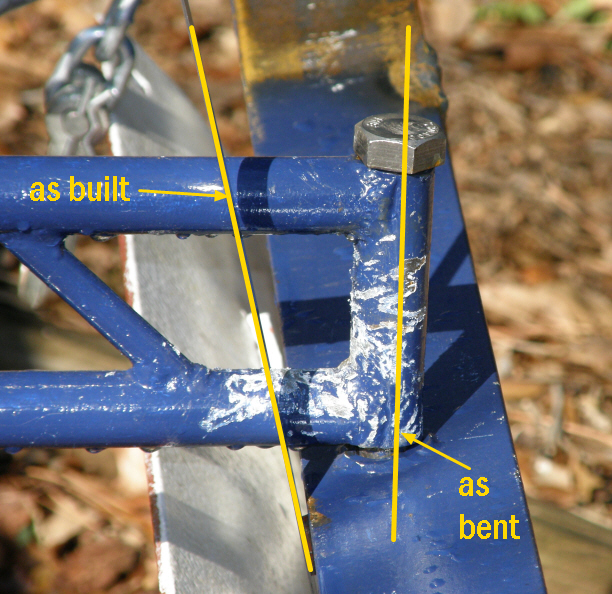

You may recall that the 3/4" stainless steel bolt attaching the rear blade to the Fast Hitch arm was parallel to the front face of horizontal blade mounting angle iron in the earlier thread. After a few minutes moving some wet sand in the backyard, I noticed the blade angle had changed. Here is a shot looking at the Fast Hitch/rear blade attachment point showing the axis of the bolt in both the As Built and As Bent conditions.

As is typical in this kind of engineering endeavor, improving the rear blade attachment will move the failure point somewhere else. But that is ok, as long as I can move the failure point above the working threshold. The reason the Fast Hitch vertical support is so chewed up is I used the arm and a piece of chain to lift and transport rear wheel weights from the "3 Cubs" roadtrip. I believe that the arm and the frame holding the blade are basically sound designs and will fail well above the intended working limit.

To correct the blade attachment failure, I'm planning on adding another horizontal angle iron below the blade verticals. This new horizontal piece will act as the lower anchor for a new vertical strap that will go up and wrap over the pivot point. Here is a sketch of the proposed mods. This is looking at the end of the blade. The portions in gray are existing and the gold items are the mods.

I think these mods will be enough to make the back blade a useful tool. We'll see what happens after the mods are added and field tested.

Rick (this is almost like engineering) Dulas

BTW can you move the chain links to set the angle?

BTW can you move the chain links to set the angle?