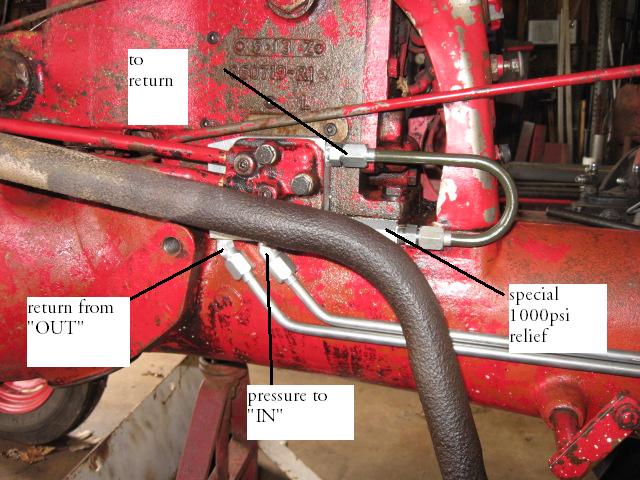

You are correct, on both counts. Furthermore, if you do have a relief valve in the new valve and don't plumb it correctly, you still may in effect dead end the system. The return through the relief valve needs to go straight back to the reservoir, not the bypass block.

That Prince valve does not appear to be a power beyond valve. Any flow from the relief valve is evidently dumped to the "out" connection. As I said previously, that "out" needs to run directly to the reservoir. If it is plumbed back into the bypass block, there is a risk of over-pressuring the system.

If I bought the valve that SamsFarm showed and used it on my cub, I would plumb the "OUT" back to the bypass block return, not the reservoir. I must be missing something. If I plumbed the out to the reservoir, where are you picking up fluid to enter the bypass block to supply the T/C. Are you saying if you hit a hard stop on the new valve and hit a hard stop on the T/C unit, you could possibly damage something or are you just comparing apples and oranges with different valve setups.