This site uses cookies to maintain login information on FarmallCub.Com. Click the X in the banner upper right corner to close this notice. For more information on our privacy policy, visit this link: Privacy Policy

NEW REGISTERED MEMBERS: Be sure to check your SPAM/JUNK folders for the activation email.

193 plow question

Forum rules

Notice: For sale and wanted posts are not allowed in this forum. Please use our free classifieds or one of our site sponsors for your tractor and parts needs.

Notice: For sale and wanted posts are not allowed in this forum. Please use our free classifieds or one of our site sponsors for your tractor and parts needs.

-

BullDAWG

- 10+ Years

- Posts: 855

- Joined: Fri Dec 30, 2011 6:09 pm

- Zip Code: 39401

- Tractors Owned: 1950 Super A

1955 John Deere 60 (sold)

1950 Cub (sold) 1950 Cub l59 woods belly mower (sold)

1951 Cub (sold) 1950 Cub w/ 5' sicklebar (sold)

Tufline 6' disc (old heavy pull type)

1953+ A-295A 2 furrow SlatWing Plow Chief plow (SA)

1950 cub-193 1 furrow SWPC plow (cub) (sold)

6' home made bush hog. Mounts on drawbar - Circle of Safety: Y

193 plow question

The coulter on the 193, is it supposed to be able to rotate left n right (swivel) ??? On mine the bolt that goes into a cast sleeve that fits into the fork that the coulter rotates in was frozen and can't be removed. I wanted to make something that could hold the bolt but it won't rotate. Im on phone so I can't post the parts pics ATM.

- Rick Spivey

- Cub Pro

- Posts: 2778

- Joined: Sun Jul 01, 2007 10:07 pm

- Zip Code: 29518

- Circle of Safety: Y

- Location: SC, Cades 29518

Re: 193 plow question

I'm fairly certain that mine rotates a few degrees left and right, I presume to move around small obstructions and such. But the movement is limited.

Rick Spivey

'52 Cub ("Great Personality") 148xxx

'48 Cub with FH ("Gunny Cub") 38xxx

'57 Lambretta (a slow work in progress)

'74 Triumph TR6 (Mama's toy)

'52 Cub ("Great Personality") 148xxx

'48 Cub with FH ("Gunny Cub") 38xxx

'57 Lambretta (a slow work in progress)

'74 Triumph TR6 (Mama's toy)

- MiCarl

- 5+ Years

- Posts: 581

- Joined: Sat Dec 16, 2017 8:28 am

- Zip Code: 48154

- Tractors Owned: 2021 RK25 "Barbie"

1944 Farmall H

1948 Farmall Cub (SOLD)

1994 Speedex 1631 - Circle of Safety: Y

- Location: Howell, MI

Re: 193 plow question

The fork should be able to pivot on the sleeve. There should be a little piece of angle on the bottom of the assembly that limits how far the fork can swing.

It sounds like you're going to need to force/cut that bolt out then get the rest apart and cleaned up.

It sounds like you're going to need to force/cut that bolt out then get the rest apart and cleaned up.

1944 Farmall H

1948 Farmall Cub

1994 Speedex 1631

1948 Farmall Cub

1994 Speedex 1631

-

BullDAWG

- 10+ Years

- Posts: 855

- Joined: Fri Dec 30, 2011 6:09 pm

- Zip Code: 39401

- Tractors Owned: 1950 Super A

1955 John Deere 60 (sold)

1950 Cub (sold) 1950 Cub l59 woods belly mower (sold)

1951 Cub (sold) 1950 Cub w/ 5' sicklebar (sold)

Tufline 6' disc (old heavy pull type)

1953+ A-295A 2 furrow SlatWing Plow Chief plow (SA)

1950 cub-193 1 furrow SWPC plow (cub) (sold)

6' home made bush hog. Mounts on drawbar - Circle of Safety: Y

Re: 193 plow question

I don't have a torch or drill press so here is what I'm having to do...

- MiCarl

- 5+ Years

- Posts: 581

- Joined: Sat Dec 16, 2017 8:28 am

- Zip Code: 48154

- Tractors Owned: 2021 RK25 "Barbie"

1944 Farmall H

1948 Farmall Cub (SOLD)

1994 Speedex 1631 - Circle of Safety: Y

- Location: Howell, MI

Re: 193 plow question

Don't drill it all the way. Once you're down to 1/4 inch or so you can probably easily knock it out with a punch.

1944 Farmall H

1948 Farmall Cub

1994 Speedex 1631

1948 Farmall Cub

1994 Speedex 1631

- Bill Hudson

- Team Cub

- Posts: 9522

- Joined: Wed Jul 26, 2006 10:50 am

- Zip Code: 44057

- Tractors Owned: 57 F-Cub - Dad & Mom's Cub

77 F-Cub - Red Long Stripe - Circle of Safety: Y

- Location: OH, Madison

Re: 193 plow question

BullDAWG wrote:I don't have a torch or drill press so here is what I'm having to do...

The next time you get the itch to get a new tractor or implement, stop and consider the possibility of purchasing a new tool(s) instead. I was amazed at the number of times I've used my press. I sure would hate to do without it now. You have mentioned two tools that are almost essential when working on old iron. I'm reminded of a quote, attributed to Henry Ford; ""If you need a tool and don't buy it, you will ultimately find that you have paid for it and don't have it."

Bill

-

BullDAWG

- 10+ Years

- Posts: 855

- Joined: Fri Dec 30, 2011 6:09 pm

- Zip Code: 39401

- Tractors Owned: 1950 Super A

1955 John Deere 60 (sold)

1950 Cub (sold) 1950 Cub l59 woods belly mower (sold)

1951 Cub (sold) 1950 Cub w/ 5' sicklebar (sold)

Tufline 6' disc (old heavy pull type)

1953+ A-295A 2 furrow SlatWing Plow Chief plow (SA)

1950 cub-193 1 furrow SWPC plow (cub) (sold)

6' home made bush hog. Mounts on drawbar - Circle of Safety: Y

Re: 193 plow question

So true, just I had tons of tools and equipment stolen and I'm still trying to get back all I once had along with some new toys. But I just didn't know the coulter was frozen and it will be a month before I can get the torch. So doing it by hand for now. But I knew it would take 10 times the time this way but gives me something to do till then.

-

BullDAWG

- 10+ Years

- Posts: 855

- Joined: Fri Dec 30, 2011 6:09 pm

- Zip Code: 39401

- Tractors Owned: 1950 Super A

1955 John Deere 60 (sold)

1950 Cub (sold) 1950 Cub l59 woods belly mower (sold)

1951 Cub (sold) 1950 Cub w/ 5' sicklebar (sold)

Tufline 6' disc (old heavy pull type)

1953+ A-295A 2 furrow SlatWing Plow Chief plow (SA)

1950 cub-193 1 furrow SWPC plow (cub) (sold)

6' home made bush hog. Mounts on drawbar - Circle of Safety: Y

Re: 193 plow question

What should have taken an hour took almost a week but finally got the bolt out.

Now I hav another question...

Both the fork arm that holds the coulter and the bushing that had the stuck bolt in it have bushings. But they are tight. If it's supposed to swivel they shouldn't be. Does those parts supposed to have bushings????

Now I hav another question...

Both the fork arm that holds the coulter and the bushing that had the stuck bolt in it have bushings. But they are tight. If it's supposed to swivel they shouldn't be. Does those parts supposed to have bushings????

- MiCarl

- 5+ Years

- Posts: 581

- Joined: Sat Dec 16, 2017 8:28 am

- Zip Code: 48154

- Tractors Owned: 2021 RK25 "Barbie"

1944 Farmall H

1948 Farmall Cub (SOLD)

1994 Speedex 1631 - Circle of Safety: Y

- Location: Howell, MI

Re: 193 plow question

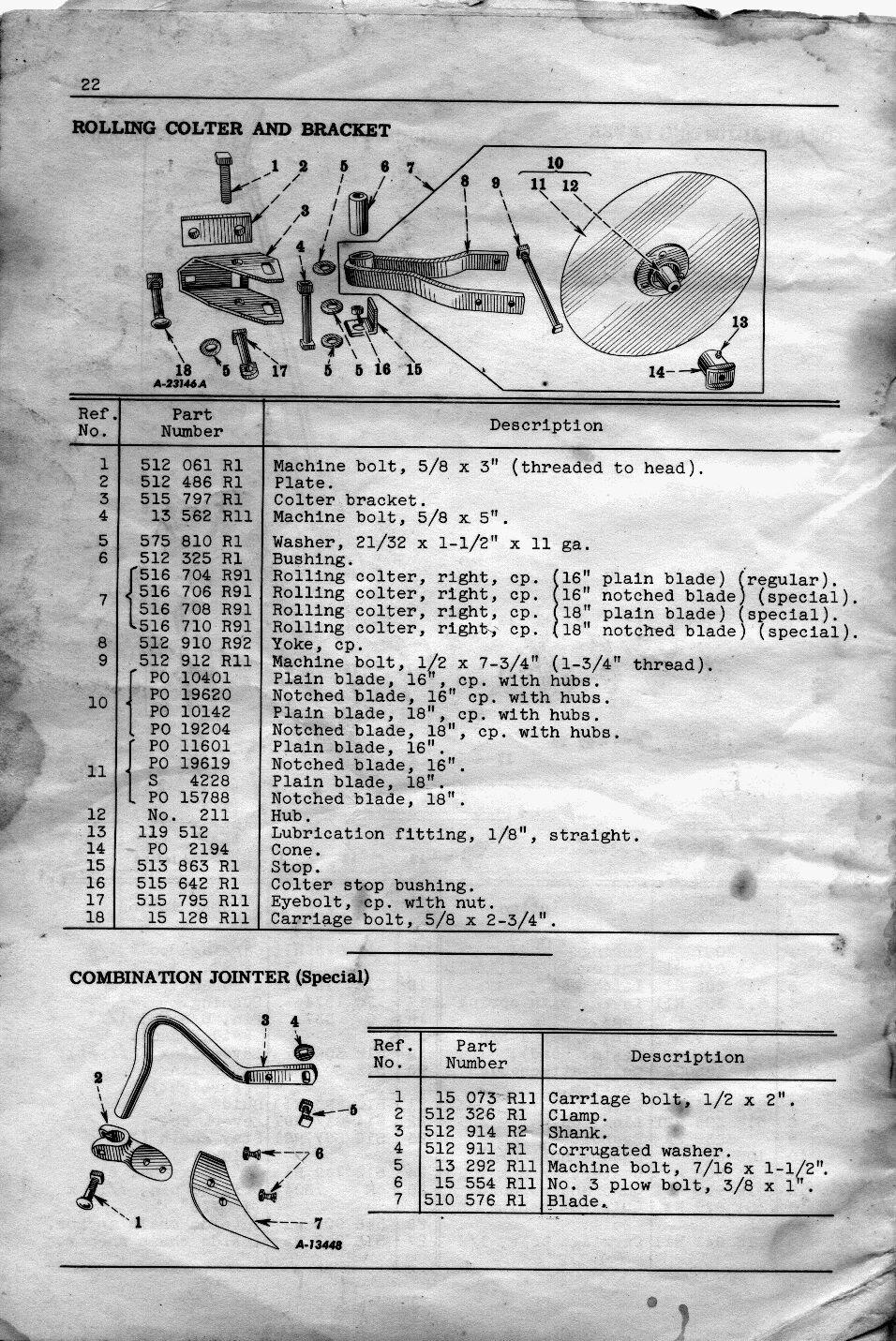

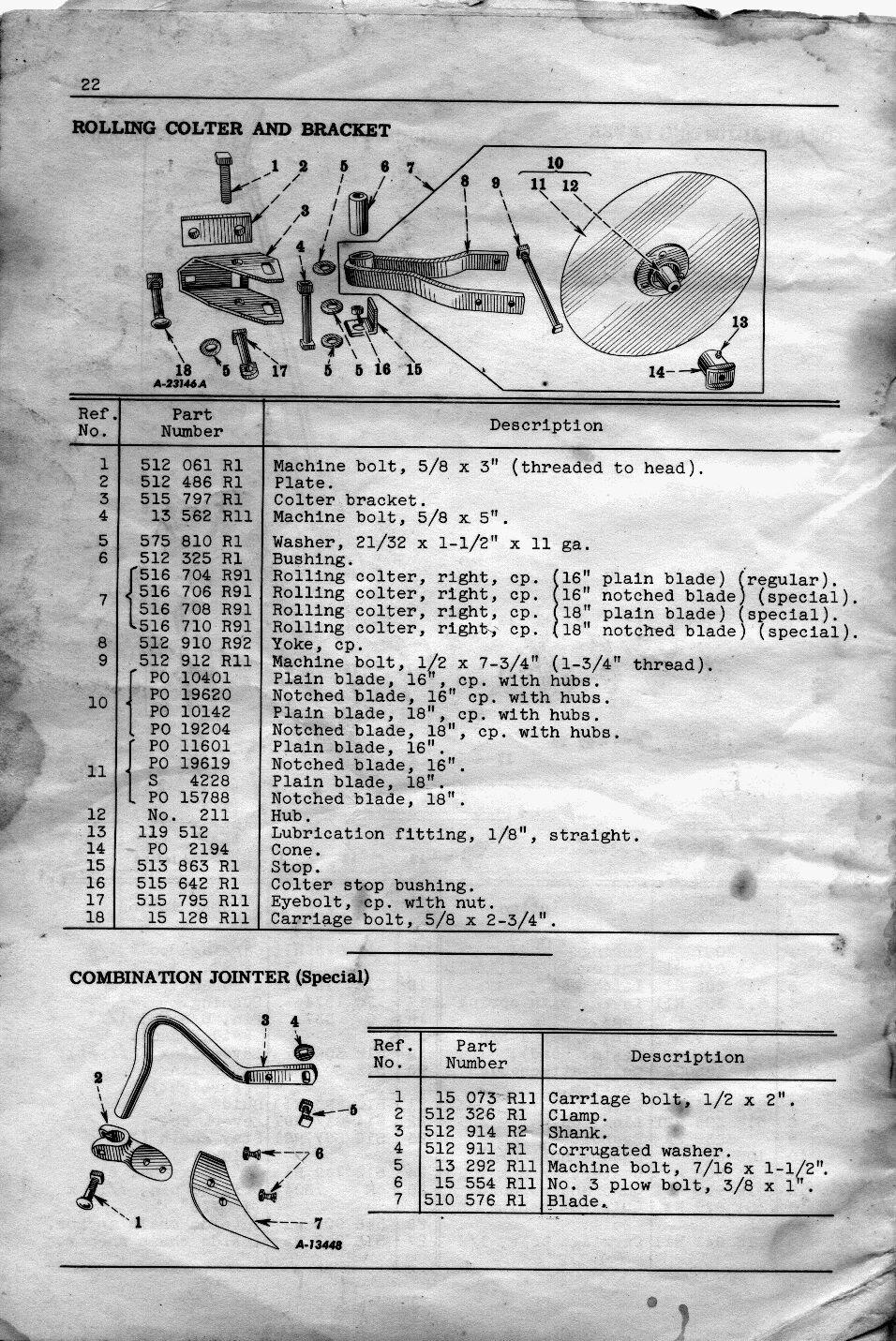

You might find this helpful:

Not all the colters have parts 1 and 17. On mine, the washers (#5) are outside the bracket (#3) and stop bushing (#116)

193 Plow Manual

In hindsight, when I had mine apart I wish I'd put a zerk fitting in the yoke to lube the bushing. Next time I have it apart I might do that.

I think you might have shortened the bushing (#6) when you cut it apart. You might need to build it up or shim it. You need to be able to clamp the bracket tight against it to keep the colter set where you want it. The bushing clamps into the bracket and the yoke pivots on the bushing.

Not all the colters have parts 1 and 17. On mine, the washers (#5) are outside the bracket (#3) and stop bushing (#116)

193 Plow Manual

In hindsight, when I had mine apart I wish I'd put a zerk fitting in the yoke to lube the bushing. Next time I have it apart I might do that.

I think you might have shortened the bushing (#6) when you cut it apart. You might need to build it up or shim it. You need to be able to clamp the bracket tight against it to keep the colter set where you want it. The bushing clamps into the bracket and the yoke pivots on the bushing.

1944 Farmall H

1948 Farmall Cub

1994 Speedex 1631

1948 Farmall Cub

1994 Speedex 1631

-

BullDAWG

- 10+ Years

- Posts: 855

- Joined: Fri Dec 30, 2011 6:09 pm

- Zip Code: 39401

- Tractors Owned: 1950 Super A

1955 John Deere 60 (sold)

1950 Cub (sold) 1950 Cub l59 woods belly mower (sold)

1951 Cub (sold) 1950 Cub w/ 5' sicklebar (sold)

Tufline 6' disc (old heavy pull type)

1953+ A-295A 2 furrow SlatWing Plow Chief plow (SA)

1950 cub-193 1 furrow SWPC plow (cub) (sold)

6' home made bush hog. Mounts on drawbar - Circle of Safety: Y

Re: 193 plow question

I seriously thought about adding a zerk fitting to mine. In the last pic u can see where it looks like one should go.

-

BullDAWG

- 10+ Years

- Posts: 855

- Joined: Fri Dec 30, 2011 6:09 pm

- Zip Code: 39401

- Tractors Owned: 1950 Super A

1955 John Deere 60 (sold)

1950 Cub (sold) 1950 Cub l59 woods belly mower (sold)

1951 Cub (sold) 1950 Cub w/ 5' sicklebar (sold)

Tufline 6' disc (old heavy pull type)

1953+ A-295A 2 furrow SlatWing Plow Chief plow (SA)

1950 cub-193 1 furrow SWPC plow (cub) (sold)

6' home made bush hog. Mounts on drawbar - Circle of Safety: Y

Re: 193 plow question

My other question was on part #8 I have what looks like a bronze bushing and in part #6 is a steel bushing. Is that right as diagrams don't show them...

- MiCarl

- 5+ Years

- Posts: 581

- Joined: Sat Dec 16, 2017 8:28 am

- Zip Code: 48154

- Tractors Owned: 2021 RK25 "Barbie"

1944 Farmall H

1948 Farmall Cub (SOLD)

1994 Speedex 1631 - Circle of Safety: Y

- Location: Howell, MI

Re: 193 plow question

Not sure what you're talking about...... Only 2 bushings on mine, #6 and #16. The #16 bushing on mine is also steel, but is a replacement so it could have originally been bronze.

Every part on my colter is in the diagram above. Nothing extra. Mine doesn't have parts 1 and 17, and there is no hole in the bracket for bolt #1 to pass through. From the pictures it appears yours does have them.

One side hole in the yoke (#8) is threaded. The bolt (9) is tightened until the cones (#14) have the correct preload and then the nut is tightened against the yoke to keep the bolt from turning. Nothing in the manual about how to adjust it, I just tighten until the blade resists turning and then back it off a hair.

Every part on my colter is in the diagram above. Nothing extra. Mine doesn't have parts 1 and 17, and there is no hole in the bracket for bolt #1 to pass through. From the pictures it appears yours does have them.

One side hole in the yoke (#8) is threaded. The bolt (9) is tightened until the cones (#14) have the correct preload and then the nut is tightened against the yoke to keep the bolt from turning. Nothing in the manual about how to adjust it, I just tighten until the blade resists turning and then back it off a hair.

1944 Farmall H

1948 Farmall Cub

1994 Speedex 1631

1948 Farmall Cub

1994 Speedex 1631

-

BullDAWG

- 10+ Years

- Posts: 855

- Joined: Fri Dec 30, 2011 6:09 pm

- Zip Code: 39401

- Tractors Owned: 1950 Super A

1955 John Deere 60 (sold)

1950 Cub (sold) 1950 Cub l59 woods belly mower (sold)

1951 Cub (sold) 1950 Cub w/ 5' sicklebar (sold)

Tufline 6' disc (old heavy pull type)

1953+ A-295A 2 furrow SlatWing Plow Chief plow (SA)

1950 cub-193 1 furrow SWPC plow (cub) (sold)

6' home made bush hog. Mounts on drawbar - Circle of Safety: Y

Re: 193 plow question

BullDAWG wrote:My other question was on part #8 I have what looks like a bronze bushing and in part #6 is a steel bushing. Is that right as diagrams don't show them...

What I'm talking about is part #8 and 6 have bushings in them looks almost like paper thin bronze and steel ones inserts.

(Note bronze one looks like its thick on one side but it's from folding over when I cut the bolt, since then I've cut off the excess and made a chamfered end on it)

Top pic shows the bronze and bottom one you can see the steel inserts. My question is "are these original" as with them all the parts including the bolt going through the bushing is tight. It can swivel but isn't free moving, you must exert force to make it swivel. Only a few pounds but still not totally free moving. And especially the bolt as I wallered the bushing when drilling out old bolt so I would think it should be free not snug. I'm thinking it was worn out and someone added them to tighten up sloppy fit from some well used parts.

- MiCarl

- 5+ Years

- Posts: 581

- Joined: Sat Dec 16, 2017 8:28 am

- Zip Code: 48154

- Tractors Owned: 2021 RK25 "Barbie"

1944 Farmall H

1948 Farmall Cub (SOLD)

1994 Speedex 1631 - Circle of Safety: Y

- Location: Howell, MI

Re: 193 plow question

The steel bushing doesn't need to swing on the bolt. It needs to be clamped tight to control the left-right position of the colter yoke relative to the plow bottom.

The yoke needs to swing fairly freely on the bushing. I don't recall any bronze in my yoke, but I may have overlooked it, might not be readily apparent if not cleaned up by a saw blade. I suppose it's possible that the yoke came with the bronze bushing pressed in so there isn't a 2nd item in the parts diagram. If the yoke moves freely on the bushing I wouldn't worry about the bronze liner.

The yoke needs to swing fairly freely on the bushing. I don't recall any bronze in my yoke, but I may have overlooked it, might not be readily apparent if not cleaned up by a saw blade. I suppose it's possible that the yoke came with the bronze bushing pressed in so there isn't a 2nd item in the parts diagram. If the yoke moves freely on the bushing I wouldn't worry about the bronze liner.

1944 Farmall H

1948 Farmall Cub

1994 Speedex 1631

1948 Farmall Cub

1994 Speedex 1631

-

BullDAWG

- 10+ Years

- Posts: 855

- Joined: Fri Dec 30, 2011 6:09 pm

- Zip Code: 39401

- Tractors Owned: 1950 Super A

1955 John Deere 60 (sold)

1950 Cub (sold) 1950 Cub l59 woods belly mower (sold)

1951 Cub (sold) 1950 Cub w/ 5' sicklebar (sold)

Tufline 6' disc (old heavy pull type)

1953+ A-295A 2 furrow SlatWing Plow Chief plow (SA)

1950 cub-193 1 furrow SWPC plow (cub) (sold)

6' home made bush hog. Mounts on drawbar - Circle of Safety: Y

Re: 193 plow question

The bolt and steel bushing is what seems to be turning. The bronze bushing fits tight against part # 6 and 8. I'm thinking of removing it and cutting off where it overlaps inside the fork. If that's still tight I'll see if I can hone it out some. (Wish I had a hone for drum breaks) as my cylinder hones are way too big (3"-5" bore). So I'll have to figure a redneck or shade tree way of doing it.

Who is online

Users browsing this forum: No registered users and 15 guests